I-GMSB-03 Auto Part Water Pump OE 9025153 Ifanele i-Cruze 2009-2016

1.Lena iphampu yamanzi eyimishini evamile;izinjini eziningi njengamanje zisebenzisa amaphampu amanzi ayimishini.Iphampu yamanzi eyimishini ishayelwa yi-crankshaft yenjini ngaphandle (njengebhande lokudlulisa), futhi ijubane layo lilingana nejubane lenjini.Uma injini isebenza ngaphansi kwezimo zesivinini esikhulu kanye nezisindayo, injini ikhiqiza ukushisa okukhulu, futhi isivinini esikhulu sepompo yamanzi sandisa ukugeleza kokujikeleza kwesipholile, okuvele kuthuthukise amandla okupholisa enjini.Ingadlulisela amandla emishini (ukujikeleza) kuwo isuka enjinini.Amandla akhiqizwayo) aguqulwa abe amandla angaba khona (okungukuthi ukuphakamisa) kanye namandla e-kinetic (okungukuthi izinga lokugeleza) oketshezi (amanzi noma i-antifreeze).Amaphampu amanzi ezimoto amaphampu amaphakathi.Umsebenzi wayo ukupompa into epholile ukuze isipholile sigeleze kumzila wokupholisa wenjini ukususa ukushisa okukhiqizwa lapho injini isebenza futhi kugcinwe izinga lokushisa elivamile lenjini.Ukwehluleka okuvame kakhulu kwezinjini zezimoto, njengokugwedla kwepiston, ukuqhunyiswa, ukuvuza kwangaphakathi kwepunch yesilinda, umsindo omkhulu odalekayo, ukwehla kwamandla okusheshisa, njll., konke kungenxa yezinga lokushisa elingavamile lokusebenza, ukucindezela okukhulu, kanye nesimo esibi sesistimu yokupholisa injini yemoto Futhi yabangela.

2. Ngokwezibalo, emhlabeni, u-20% wokuhluleka kwenjini yokulayisha ukukhanya kuvela ekuhlulekeni kwesistimu yokupholisa, futhi u-40% wokuhluleka kwenjini yomthwalo osindayo uvela ekuhlulekeni kwesistimu yokupholisa.Ngakho-ke, ukugcinwa kwesayensi nokunengqondo kwezinhlelo zokupholisa kubaluleke kakhulu ekusebenzeni okujwayelekile kwezinjini zezimoto.

3.Kunezingxenye ezinhlanu eziyinhloko zephampu yamanzi: indlu, i-bearing, i-water seal, i-hub / i-pulley kanye ne-impeller.Kukhona nezinye izesekeli, njengama-gaskets, ama-O-rings, ama-bolts, njll.

4. Isikhwama sepompo yamanzi: Isikhwama sepompo yamanzi siyisisekelo lapho zonke ezinye izingxenye zifakwa futhi zixhunywe enjinini.Ivamise ukwenziwa ngensimbi eyinsimbi noma i-aluminium eyi-cast (izinqubo zokuphonsa kanye ne-die-casting).Iphinde yenziwe nge-PM-7900 (i-dust resin. Kanye nezinto zensimbi ezigoqeke ngokubanda. Le modeli igobolondo le-aluminum elidonsa kanzima.

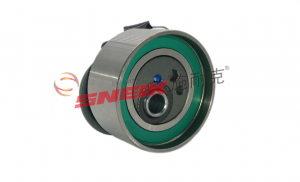

5.I-Bearing: Ibhekene kakhulu nokudluliswa kwamandla.Yakhiwe izingxenye ezimbalwa ezibalulekile ezifana ne-mandrel, insimbi yebhola/i-roller, i-ferrule, ikheji, uphawu, njll.I-bearing iyi-double row ball bearing (uhlobo lwe-WB).

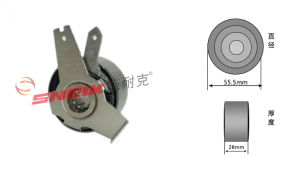

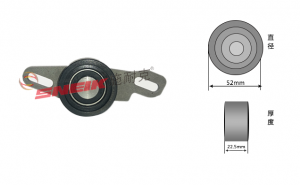

Ihabhu lamasondo: Amaphampu amanzi amaningi awanawo ama-pulley, kodwa anamahabhu.Lolu hlobo luyihabhu le-disc, futhi impahla yalo i-ductile iron pulley/hub.

I-impeller: I-impeller yakhiwe nge-radial linear noma iblade emise okwe-arc kanye nomzimba, futhi isebenzisa i-torque ejikelezayo eyethulwa yi-bearing shaft ukuze iphampe into epholile kusistimu yokupholisa injini ukuze ijikeleze.Idivayisi eqedela ukuguqulwa kwamandla, ngokuzungezisa, isheshisa ukugeleza koketshezi, iqedele umjikelezo wokupholisa nokushisa wamanzi noma isinqanda-qhwa, futhi ifinyelela injongo yokupholisa injini.Lena impeller yensimbi egoqiwe ebandayo.

I-water seal iyisisetshenziswa sokuvala sephampu yamanzi.Umsebenzi waso ukuvala isipholile ukugwema ukuvuza, futhi ngesikhathi esifanayo ukuhlukanisa okupholisayo nephampu yamanzi ukuvikela ukuthwala.Izingxenye zayo eziyinhloko ezisebenzayo yiringi ehambayo nendandatho emile.Indandatho emile igxilile egobolondweni, futhi indandatho enyakazayo izungeza ne-shaft.Ngesikhathi senqubo, izindandatho eziguquguqukayo nezimile ziyagudlana futhi kufanele zigcinwe zivaliwe.Impahla yendandatho eguquguqukayo ngokuvamile yenziwe nge-ceramics (ukucushwa okuvamile) kanye ne-silicon carbide (ukucushwa okuphezulu), futhi indandatho emile ngokuvamile yenziwe nge-graphite (ukucushwa okuvamile) noma i-carbon graphite (ukumiswa okuphezulu).) Manje imikhiqizo yethu yonke yenziwe ngezinto ezisezingeni eliphezulu ze-carbon graphite.

(1) Faka iringi yerabha evalayo endaweni ngaphambi kokufaka iphampu yamanzi

(2) Ngemva kokufakwa kwepompo yamanzi, kuyadingeka ukuthola izikhala ezivundlile neziqondile phakathi kwe-inlet yamanzi yepompo yamanzi kanye nokuhlangana kwekhanda le-cylinder.Kusetshenziswa igeji yokuhlola i-feelleer ukuze kutholwe igebe le-longitudinal phakathi kwendawo yokungena amanzi yepompo kanye nekhanda lesilinda ukuze kuqinisekiswe ukuthi ihlangabezana nezidingo)

(3) Indawo yokufaka iphampu kufanele ihlanzwe ngokucophelela futhi ilinganiswe

(4) Lapho ufaka iphampu yamanzi, iringi yerabha evalayo yepompo yamanzi kufanele imanziswe ngesipholile kuqala.Uma i-sealant idingeka, ukunakekelwa kufanele kuthathwe ukuthi ungafaki ngokweqile

(5) Lapho ushintsha iphampu yamanzi, isistimu yokupholisa kufanele ihlanzwe, ngoba ukungcola, ukugqwala nezinye izinto zangaphandle ohlelweni lokupholisa kuzodala imihuzuko endaweni yokuvala uphawu lwamanzi, okuholela ekuvuzeni kwepompo yamanzi.

(6) Sebenzisa isipholile sekhwalithi ephezulu, ungagcwalisi isipholile esisetshenzisiwe nesisezingeni eliphansi, ngoba isipholile sekhwalithi ephansi noma amanzi awanawo ama-anti-corrosion agents, angabangela ukugqwala kwesistimu yokujikeleza kanye nomzimba wephampu yamanzi, futhi futhi ukusheshisa ukuwohloka kophawu lwamanzi Ukugqwala nokuguga ekugcineni kuzoholela ekuvuzeni kwepompo yamanzi (engeza uhlobo olujwayelekile lwe-antifreeze ehlangabezana nezindinganiso zikazwelonke).Kunconywa ukusebenzisa i-antifreeze ekhethekile yenkampani

(7) Amandla okucindezela ebhande lepompo lamanzi kufanele afanele, futhi kufanele asetshenziswe ngokuhambisana ngokuqinile nemininingwane yokulungisa.Uma amandla okucindezela amancane kakhulu, ibhande lizoshelela futhi libangele umsindo, futhi ezimweni ezimbi kakhulu, iphampu yamanzi ngeke isebenze ngokujwayelekile.Ukuqina okweqile kwebhande kuzodala ukuthi i-bearing ilayishe futhi ibangele ukulimala kwangaphambi kwesikhathi, futhi ukuthwala kuzophuka.